- An ISO 9001:2015, 14001:2015 & 45001:2018 Company

What are Water-Blocking Cables? How do they Work?

Water-blocking cables or Water-Resistant Cables are a useful innovation in the cable industry. This innovation is useful, especially when moisture or water exposure is a serious concern. These water-blocking cables are designed in such a way that they can stop water from getting inside, which keeps them safe and working well even if it's wet outside. In this article, we will read about water-blocking cables, understand what these cables are and how they work.

What are Water-Blocking Cables?

The full form of TR-XLPE is Tree Retardant Cross-Linked Polyethylene. A thermoset plastic compound used for the insulation of wire and cable containing an anti-treeing compound or a type of insulation material used in cables. TR-XLPE is widely used in medium and high-voltage underground distribution and transmission cables due to its reliability and durability.

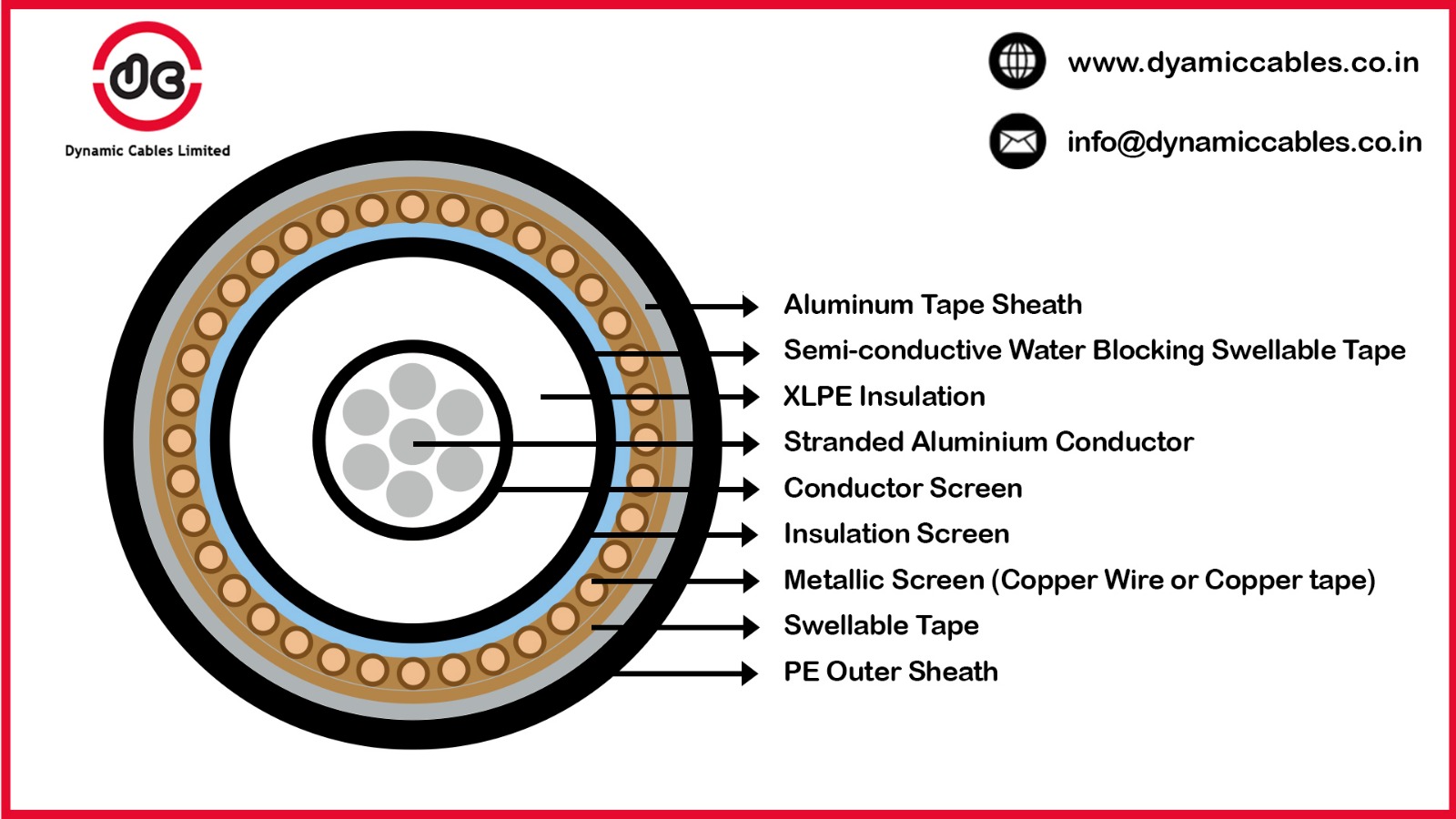

When moisture or water enters into the area of installation, it can cause cable damage or other failures. Water-blocking or Water-resistant cables are those cables that are designed to perform in different types of aquatic environments. These cables are designed to prevent water from entering and damaging the cable's insulation.

People also read: What are the Features of Water Resistant Cables?There are two ways moisture/water can enter;

- Radial Ingress: In the case of radial ingress, moisture enters the cable either by a gap through the covering or protective layers (sheaths) or by any breach in the cable. Once water has entered the cable it then travels longitudinally through it.

- Longitudinal Ingress: Water enters the cable through poorly constructed joints or terminations, inefficient end capping, and especially if jointing pits, etc., flood. This may occur when the cable is being installed, maintained or placed near moisture.

How Water-Blocking Cables Work?

As water-blocking cables are designed to prevent moisture or water from entering and damaging the cable. They employ various methods to achieve this, ensuring the cable's longevity and functionality. Below we will read about the working mechanism of Water-Blocking Cables. How do they work?

Water-blocking cables use special materials to keep water out. The outer layer, called the jacket, is the first line of defence against water. A good jacket material, like high-density polyethene (HDPE), is important for keeping water away. Choosing the right jacket can be tricky because it needs to balance strength and water resistance.

ConclusionWater-blocking cables are essential for maintaining reliable functioning in areas where there is a lot of moisture or water contact. These cables use water-blocking techniques to successfully stop the entry of water, protecting them from harm and extending their lifespan. Industries that depend on continuous connectivity need to understand the significance of water-blocking and its workings. Water-blocking cable manufacturers are constantly evolving due to advances in materials and processes, providing reliable solutions for a wide range of applications. Adopting these solutions guarantees robust infrastructure against environmental hazards.

English

English

C701, Tower-C, Noida One

C701, Tower-C, Noida One