- An ISO 9001:2015, 14001:2015 & 45001:2018 Company

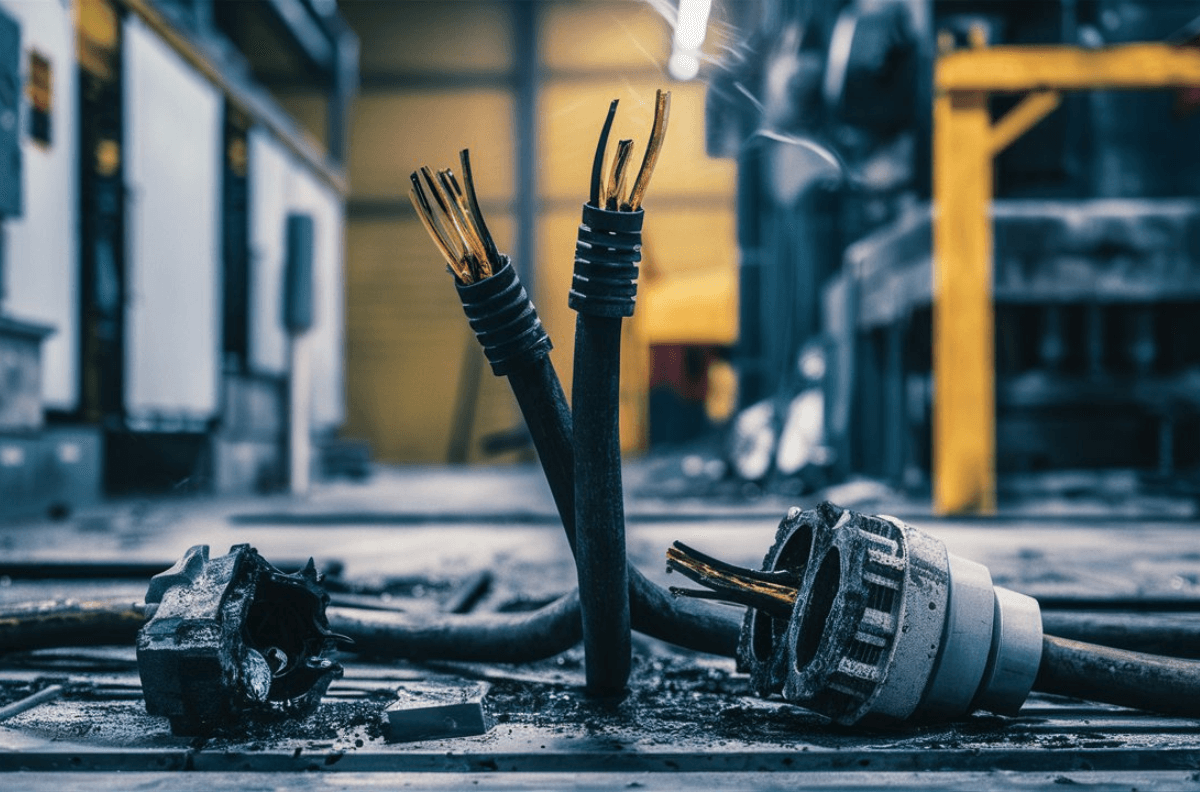

What are the Main Reasons for Electrical Cable Failure?

Electrical cable failure is a common issue in various industries, particularly in high-voltage cables. These failures can have significant consequences, ranging from functional disruptions to safety hazards. In this article, we will explore the main reasons for electrical cable failure.

Main Reasons for Failure of Electrical Cable

There are following reasons for the failure of electrical cables, these are as follows.

- Service Life of Cable: If a cable is used in conditions it wasn't designed for, its lifespan can significantly decrease. As it gets older, the materials become brittle and crack, which means it can be broken easily, which can cause the insulation and sheathing to fail. This exposes the conductor and increases the risk of short circuits, potentially leading to electrical fires.

- Application: If an electrical cable is chosen inappropriately for the application it is the chance of failing in service. Choosing a cable that matches the installation environment reduces the risk of failure.

- Loss of the Cable Sheath: The sheathing material can degrade due to factors such as extreme temperatures (Hot/Cold), chemicals, weather conditions and rubbing against surfaces. When this happens, the insulated cores are left vulnerable, which can lead to electrical failure.

- Physical Damage: If the cable gets damaged during installation or later on while being used, its strength is compromised. This damage reduces the cable's lifespan and suitability for its desired purpose.

- Cable Heating: Too much heat on the cable can lead to the insulation and sheathing materials breaking down, causing the cable to fail prematurely. This heat can come from an external source or be generated by the resistance to current flow in the conductor.

- Sun Exposure: UV rays from the sun can affect the insulation and sheathing of electrical cables. Cables exposed to sunlight should either be made with UV-resistant materials containing carbon black, or shielded from UV exposure by using protective coverings like conduit (a pipe, channel). UV exposure often leads to insulation cracking, increasing the risk of short circuits.

- Electrical Overloading: Electrical overloading happens when the cable isn't strong enough for its job.

Let's end up with

Understanding the main reasons for electrical cable failure is very crucial for maintaining safety and functionality in various industries. Many factors contribute significantly to cable failures. To mitigate these risks, it's essential to choose cables designed for specific environments, handle them carefully during installation and use, and avoid overloading electrical circuits. Additionally, partnering with top reputable cable manufacturers that ensures top-quality products that meet industry standards for reliability and durability. Take proactive steps to safeguard your electrical systems by investing in cables from trusted manufacturers.

English

English

C701, Tower-C, Noida One

C701, Tower-C, Noida One