- An ISO 9001:2015, 14001:2015 & 45001:2018 Company

What are the Common Factors that Affect ACSR Conductor's Performance?

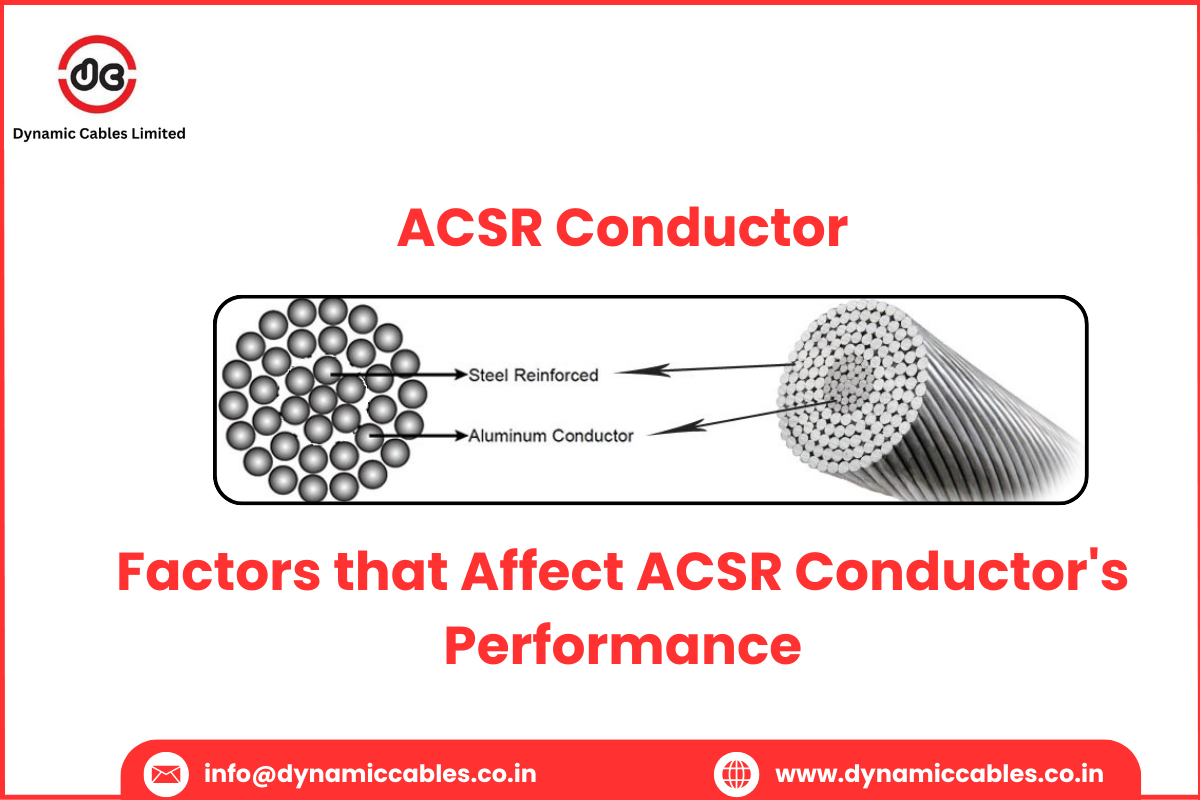

Known for their outstanding performance, Aluminum Conductor Steel Reinforced (ACSR) conductors are the foundation for industrial power transmission.

Their design blends the strong steel core for improved mechanical support with the high conductivity of aluminium for effective current flow. This leads to dependable power transmission in challenging industrial settings and over extended distances.

Still, there are times when the performance of these trustworthy conductors declines. But how? Let’s find out. This article explores the common causes that can impact the performance of ACSR conductors in practical industrial applications.

3 Factors That Affect ACSR Conductor's Performance

- (A). Overloading: Overloading, or going beyond a conductor's intended current carrying capability, can seriously affect the dependability and performance of the ACSR conductor. Overloading produces an excessive amount of heat, which can cause:

- Elevated Sag: Conducts lengthen, perhaps beyond safety thresholds, and results in flashovers.

- Decreased Current Carrying Capacity: Additional overloading results from overheated conductors' inability to manage their rated current.

- Material Degradation: Over time, intense heat erodes the conductor's strength and threatens its structural integrity.

These may result in equipment failure, power outages, or even disastrous line breakage. Industries can ensure excellent ACSR conductor performance and minimize overloading by putting proactive systems like dynamic line ratings and load monitoring into place.

- (B). Environmental Factors: ACSR conductors are exposed to various environmental factors such as extreme temperatures, wind, ice and lightning. These factors can cause thermal expansion, contraction, and mechanical stress, leading to reduced performance.

- (C). Aging over time: ACSR conductors experience ageing and wear. Prolonged or notably long exposure to harsh environmental elements, such as UV radiation, moisture, and temperature fluctuations, can degrade aluminium and steel components.

Conclusion

In summary, even though ACSR conductors are well-known for their industrial endurance, several factors can affect how well they operate. Vigilance is essential regarding environmental risks such as UV radiation, water intrusion, overloading, and poor grounding.

Industries can ensure the continuous, dependable operation of their ACSR conductor systems by being aware of these typical reasons and putting preventative measures like material selection, load monitoring, and appropriate grounding techniques into place.

Get High-Quality ACSR Conductors For Industrial Purpose From The Best-In-Industry—Dynamic Cables!

Make sure that your industrial processes are uninterrupted by using dependable power transmission. Join hands with Dynamic Cables, the leading supplier of premium ACSR conductors in the market, for the next-level supply of these conductors.

Our dedication to quality ensures outstanding results, longevity, and steadfast customer service. Never accept anything less. Contact Dynamic Cables to discover the power of assurance.

English

English

C701, Tower-C, Noida One

C701, Tower-C, Noida One